This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping us to understand which sections of the website you find most interesting and useful.

Fast-forward to our present

Since the company’s founding in 1991, we at Detection Technology have had a strong belief in our hearts in doing things differently. By combining market knowledge and customer intimacy with technology and engineering capabilities in an innovative way, we have delivered greater customer value. Fast-forward to our present to learn how we have succeeded.

The birth

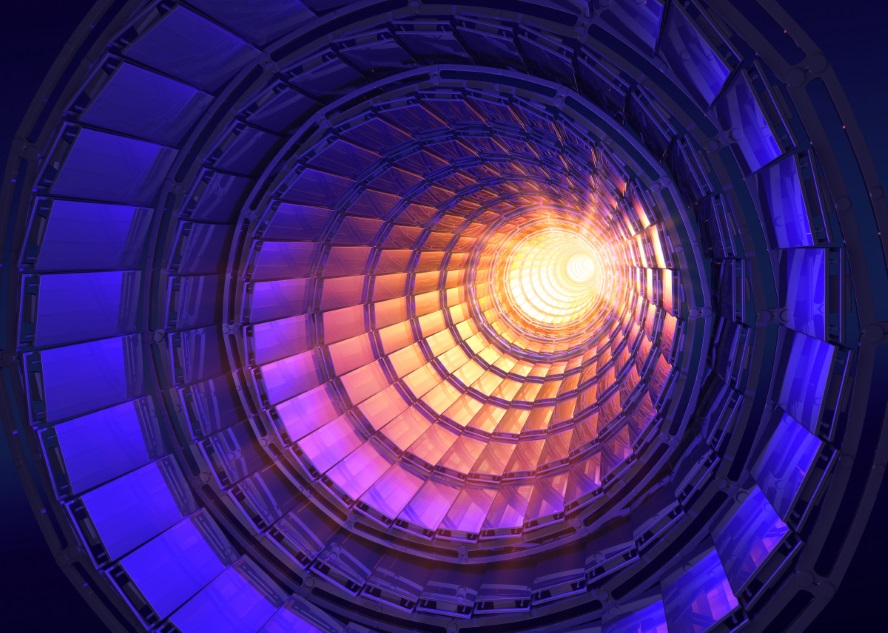

Detection Technology was founded in Espoo, Finland on 11 December 1991 by Iiro Hietanen, Tuure Tuuva and Tapio Wiik, scientists with a CERN background. CERN, the European Organization for Nuclear Research, in Switzerland is well-known for developing sensor technology for high-energy physics and space research. CERN is also the home of many successful breakthrough innovations, such as medical PET camera and the World Wide Web.

The company was founded to industrialize the ultra-sensitive sensor technology originating from the CERN research. Detection Technology started as a spin-off company from the Research Institute for High Energy Physics in Finland (SEFT), and the Technical Research Centre of Finland (VTT). CERN also played a key role in testing Detection Technology’s solutions in years that followed.

The first operational year

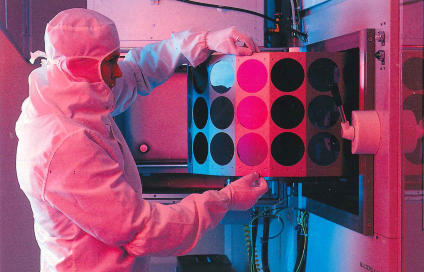

The first operational year started in VTT’s premises in Espoo. Silicon strip and pad detectors, and complimentary readout electronics and hybrids were designed and manufactured for high energy physics research.

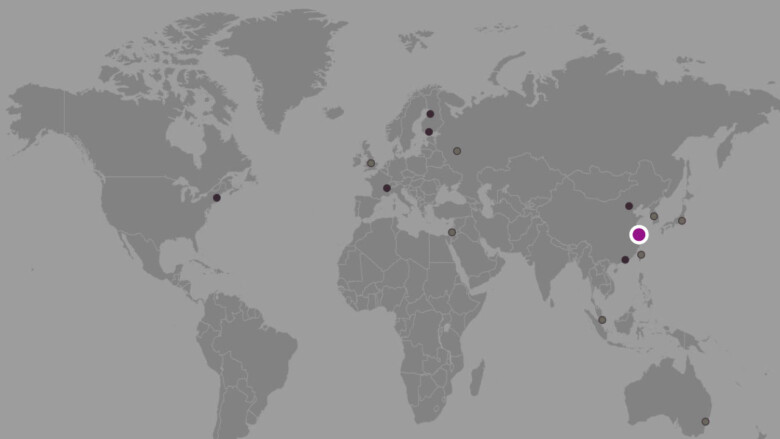

China

The first international location established to China. Cooperation with Tsinghua University, and silicon wafer processing started in Beijing.

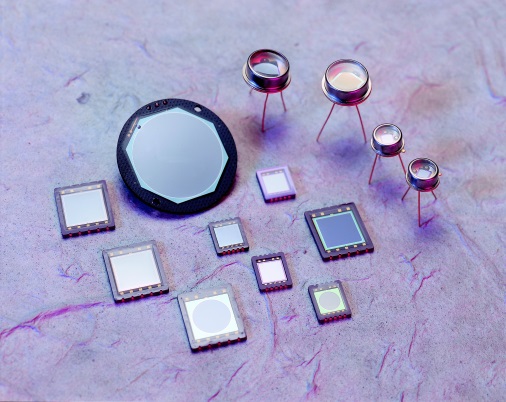

Proprietary photodiodes

Production of proprietary photodiodes started, and the first shipments to industrial customers were done.

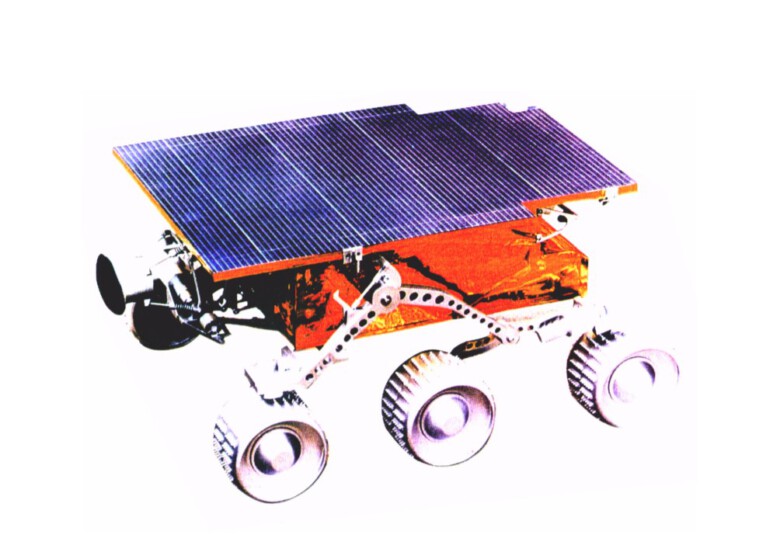

Mission on Mars

Detection Technology’s photodiode on the robotic spacecraft, Pathfinder, launched to Mars on December 4 by NASA. Pathfinder landed successfully on Mars’s Ares Vallis in July 1997, and analyzed the atmosphere, climate, geology and the soil.

FSI

Started shipments of detector solutions utilizing front side illuminated (FSI) photodiode arrays.

Facility to Ii

The new packaging and assembly facility in Ii, Finland was opened with help of Finnish government’s financial support. Premises with a clean room adjusted to the company’s specific needs to support its growth targets.

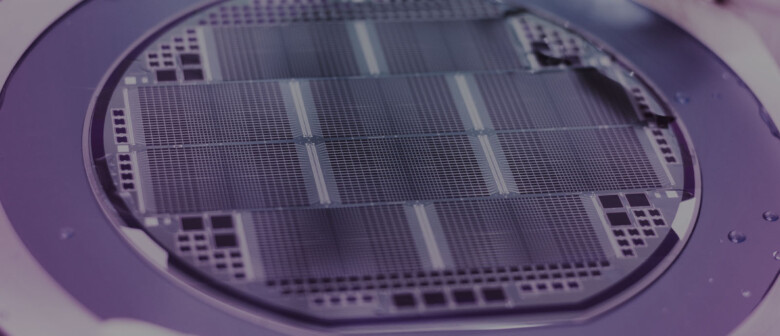

5” foundry

Photodiode wafer production started at the 5” foundry.

Revenue exceeded 1M€

Net sales totaled EUR 1.2 million in 1998, and the company employed 12 persons at the end of the year.

X-Scan introduced

X-Scan product family was introduced. Linear detector arrays for industrial X-ray inspection.

Medical CT detectors

Entered medical CT market. Since then, high-performance CT detectors has been shipped to the most stringent medical imaging solutions in the world.

X-Scan L

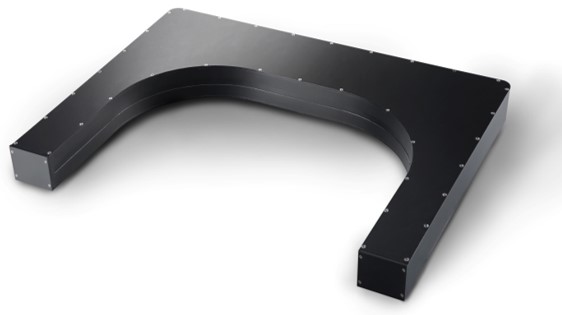

X-Scan L-shape launched globally. One of the world’s first commercial detectors for security inspection systems.

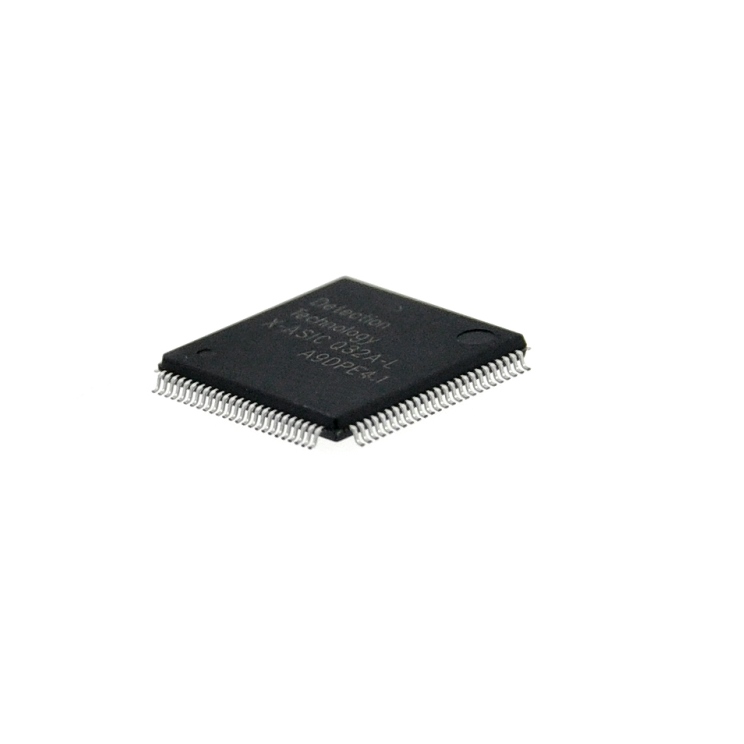

One-of-a-kind ASICs

Preamplifier ASICs introduced providing significant size and cost reduction of X-ray detector readout electronics.

Final assembly started in Beijing

Production started in Wangjing Beijing, focus on the final assembly of detector modules, and subsystems.

PCB replacing costly HTCC

Introduced a novel process to apply PCB (printed circuit board) material to replace costly HTCC (high temperature co-fired ceramic) substrates on CT detector modules. The innovation of low-cost detector module substrates was the game changer in the industry delivering remarkable cost savings for CT systems.

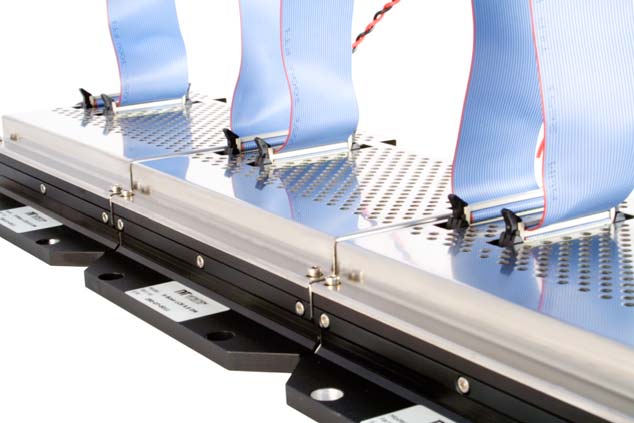

Cargo detector subsystems

High energy and performance cargo and container detector subsystems introduced.

Entered security CT market

The first X-ray detector modules designed and shipped for key players in the security CT market.

USA

An office with focus on sales and technical support established to Ohio, Greater Cleveland Area in the US.

Production expanded in Beijing

Production capability in Beijing expanded by setting up a clean room for component assembly. Volume production moved from Ii to Beijing.

Internationalization Award

The President of the Republic of Finland Tarja Halonen granted the Internationalization Award to Detection Technology for its ability to develop, and implement new operational methods in its internationalization processes.

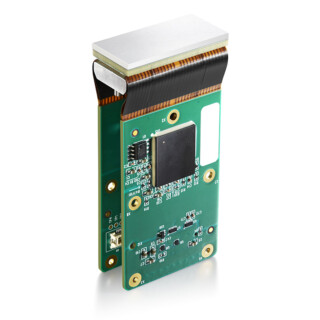

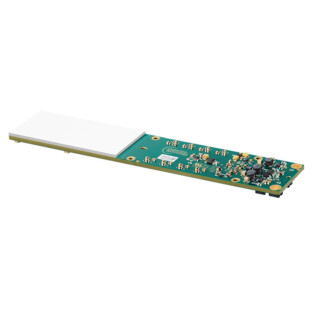

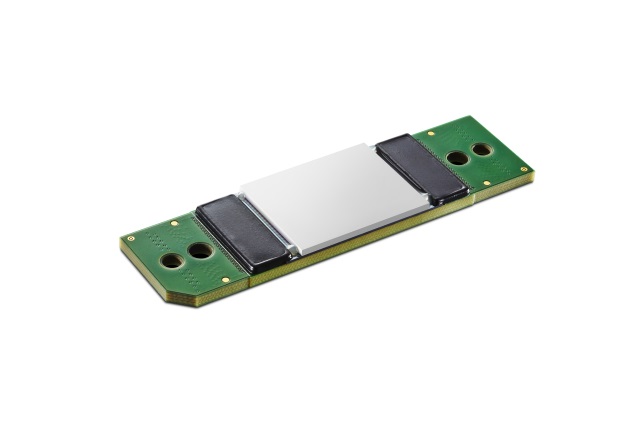

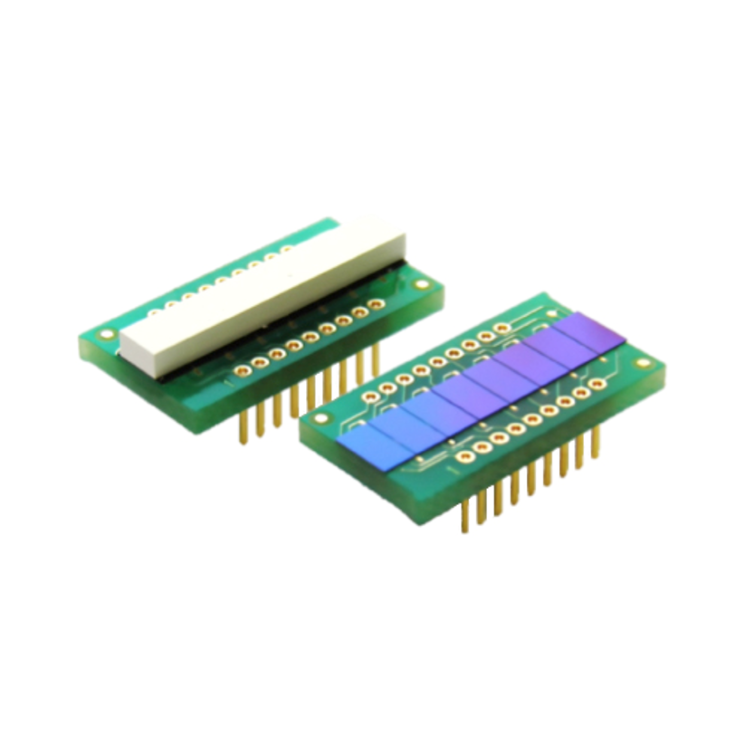

Photodiode and ASIC on same board

X-Card DE and SE series introduced to the security market. The concept combining photodiode and ASIC on the same board enabling various single and dual energy configurations without pins or sockets on the path of extremely small and sensitive photodiode current signal.

X-Scan U series

Detection Technology took tire inspection to the next level with launch of X-Scan U series.

6” foundry

Photodiode production started at the 6” foundry.

Net sales 10 M€

Net sales was EUR 9.9 million, and the company had 170 employees at the end of the year.

BSI

Shipments of imaging solutions based on back side illuminated (BSI) photodiode technology started.

To Boston

The US office moved from Greater Cleveland Area to Greater Boston Area.

Revenue 25 M€

Net sales totaled EUR 24.8 million in 2012, and the company employed 209 people at the end of the year.

Beijing site doubled

Beijing factory doubled by all measures like factory, clean room, and office floor space.

Net sales exceeded 30 M€

Net sales of 2013 totaled EUR 30.3 million, and the company had 269 employees.

Shipments for security CT accelerated

Significant ramp up of versatile detector solutions for security CT applications started.

From Ii to Oulu

Company moved its facility from Ii to Oulu. A new, class ISO 8 cleanroom established to support and speed up new product introductions.

IPO

Detection Technology successfully completed its initial public offering. The trading in Detection Technology Plc’s shares started on 16th of March 2015 on the Nasdaq First North Finland market place under the trading code DETEC.

8” foundry

Photodiode production started at the 8” foundry.

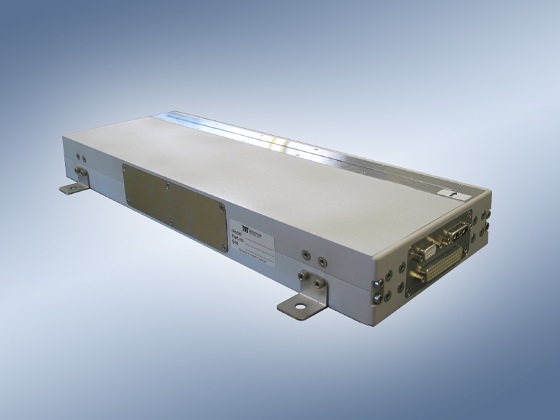

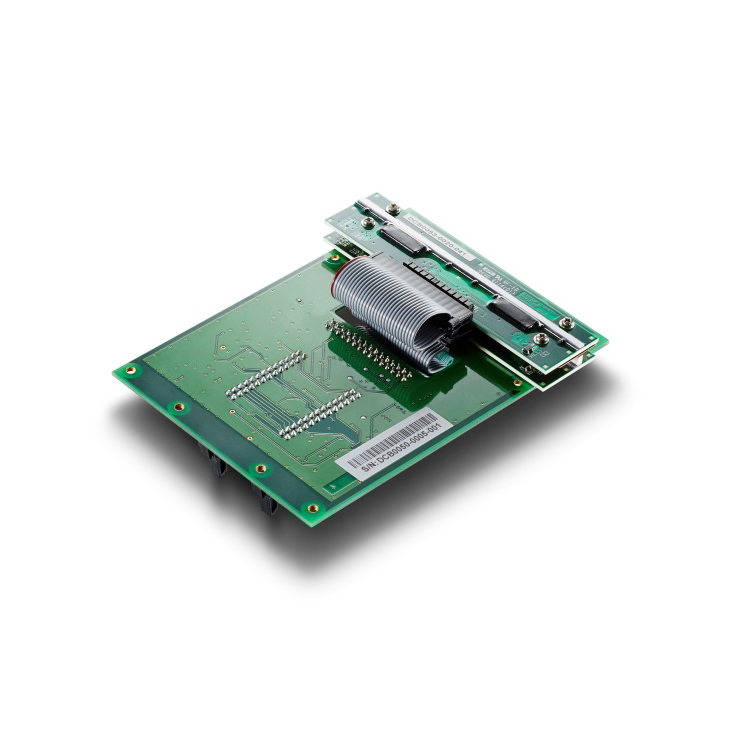

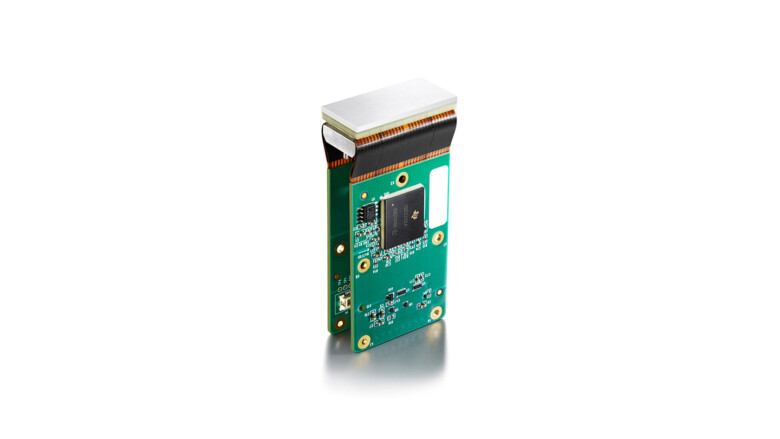

Digital X-Cards and X-GCU

A next generation digital platform introduced shortening time-to-market and delivering total cost savings for all X-ray imaging systems.

New factory to BDA

A new factory in Southeast Beijing Business Development Area (BDA) inaugurated on 4th of November. The production moved from Wangjing to BDA. R&D and sales remain in Wangjing.

Net sales over 40 M€

Net sales increased by 29.2% to EUR 42.8 million, and the company employed 341 people.

The year of digitalization

Implementation of a new digital detector platform delivering greater intelligence for next generation security and industrial X-ray imaging solutions.

BSI to standard products

Brought BSI (back-illuminated) photodiode technology, known from stringent medical CT (computed tomography) applications, to standard X-ray imaging products.

25th anniversary

To foresave has been Detection Technology’s business for 25 years. Over the quarter century, the company has shipped over one million solutions, of which around 400,000 units to power CT systems.

Net sales increased by 77%

Net sales increased by 76.5% to EUR 75.5 million, and Detection Technology had 416 employees at the end of the year.

Surpassed shipment milestone of 2.5 million units

DT celebrated a cumulative shipment milestone. The company shipped the 2.5-millionth X-ray imaging solution for a next generation security CT system from its Beijing factory.

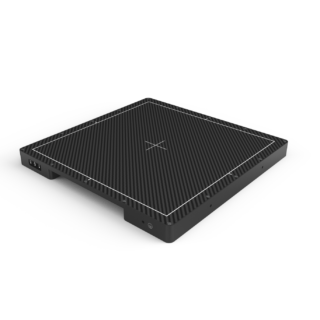

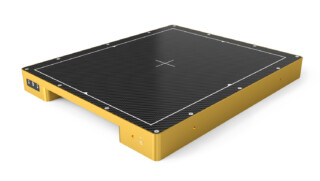

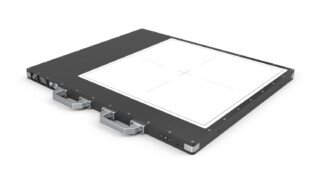

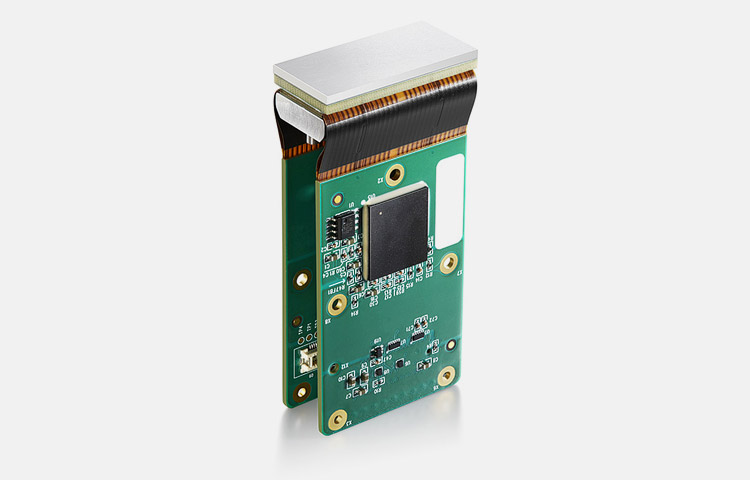

X-Tile CT detector module

DT set a new industry standard with the world’s first off-the-shelf, tileable CT detector module named X-Tile. The 4-sided buttable X-Tile meets the most stringent performance requirements of the highest tier volumetric computed tomography (CT) systems.

Provided security at 2018 Winter Olympics

DT was involved in providing security at the 2018 Winter Olympics in Pyeongchang, South Korea. The company’s X-ray detectors were utilized in the scanners used to screen goods at venues and inspect shipments before and during the games. Read more ›

Entered CMOS flat panel market with X-Panel 1511

DT entered the CMOS X-ray detector market with the X-Panel product family. The company introduced the X-Panel 1511 X-ray flat panel detector as the first solution to enhance patient experience and safety. Read more ›

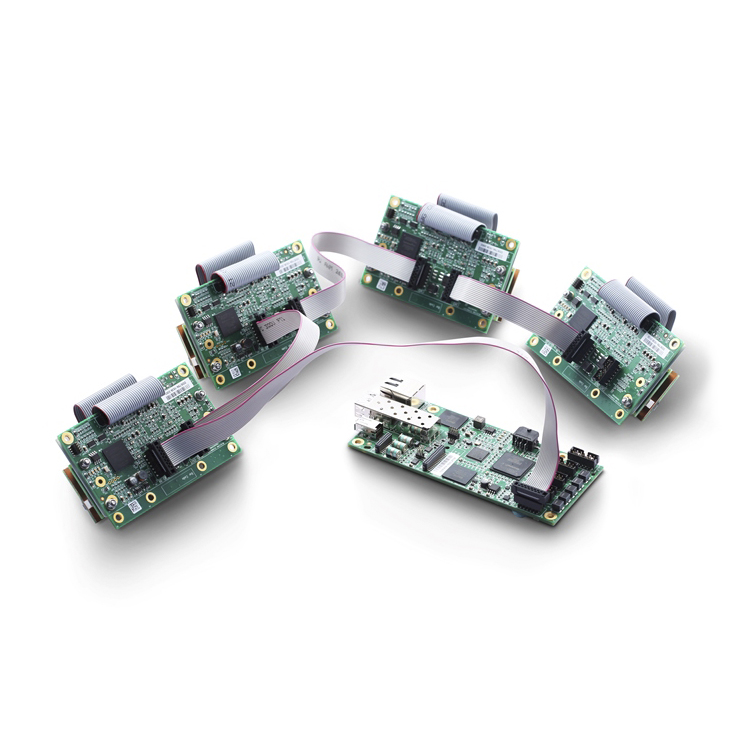

Unveiled Aurora product family

DT unveiled Aurora to deliver value in simplicity for digital X-ray imaging. The digital Aurora product family consists of a wide range of stand-alone detectors, and all the necessary building blocks, such as ready-made detector boards, modules and readout electronics, for end-to-end imaging systems.

Aurora comes with an application-specific integrated circuit (ASIC) and significantly simplified product structure. This enables faster go to market for performance-enhancing and mechanically more robust imaging solutions. Read more ›

Rolled out X-Panel 2301

DT rolled out the X-Panel 2301 flat panel detector for cephalometric imaging. Together with X-Panel 1511 it boosts all mainstream extraoral dental X-ray imaging modalities. Read more ›

Acquired business of MultiX

DT acquired the business of the French technology company MultiX S.A. The deal significantly expanded DT’s technology base and patent portfolio, thereby strengthening its position in the security, industrial and medical X-ray imaging market. Read more ›

Published an RBA-based Code of Conduct

DT published an RBA-based Code of Conduct to reinforce its commitment to grow sustainably. The company’s quality, environmental, business ethics, labor and health, and safety policies form the DT code. Read more ›

Announced rebranding of MultiX

DT announced rebranding of the MultiX business and product line. At the same time, DT introduced the X-Card ME3 detector board and the X-IM ME3 control unit, which represent the company’s new multi-energy (ME) product line. Read more ›

DT announced rebranding of the MultiX business and product line. At the same time, DT introduced the X-Card ME3 detector board and the X-IM ME3 control unit, which represent the company’s new multi-energy (ME) product line. Read more ›

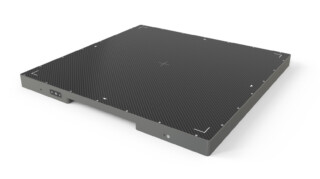

Presented the X-Tile powered panel detector for industrial applications

DT presented the X-Tile powered panel detector for industrial applications at the Digital Imaging and Ultrasonics for NDT 2019 conference in New Orleans. The solution enables real-time video monitoring of material flow at record speed. Read more ›

Awarded the ISO 13485:2016 certification

DT was awarded the ISO 13485:2016 certification for medical flat panel detectors. The certification covers the development, production, and distribution of X-ray flat panel detectors. Read more ›

DT was awarded the ISO 13485:2016 certification for medical flat panel detectors. The certification covers the development, production, and distribution of X-ray flat panel detectors. Read more ›

Expanded its product portfolio to TDI technology

DT expanded its product portfolio to TDI (Time Delay Integration) technology and launched a TDI-based camera family called X-Scan T, which is optimized for demanding industrial environments. Read more ›

Completed the new production and service site in Wuxi

The new production and service site in Wuxi, Greater Shanghai area, was completed by end of the year, and the site passed the ISO 9001:2015 certification audit on 23 December.

Launched production at the Wuxi site

DT announced the official production launch at its new production and service site in Wuxi, Greater Shanghai area. The company had completed the first customer shipments of X-Card detector boards for security line scanners. Read more ›

Rolled out the X-Scan C series

DT rolled out the X-Scan C series to trim the time-to-market and costs of industrial X-rays. The series is a perfect fit for the quality control, and sorting and grading of various goods in very harsh environments, such as the food and pharmaceutical industries with their high imaging quality and throughput time requirements. Read more ›

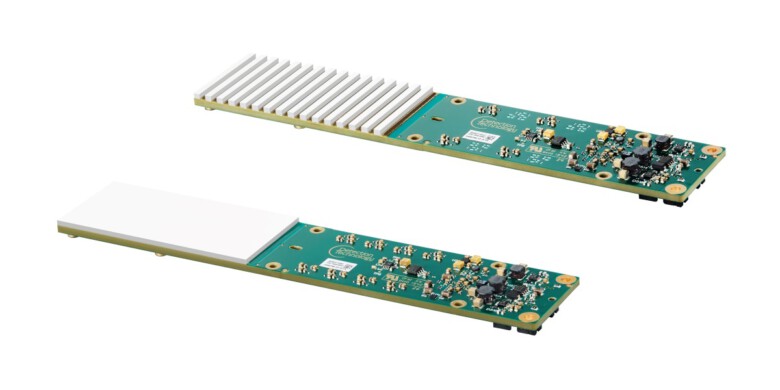

Unveiled the off-the-shelf subsystem for security CT applications

DT unveiled the industry-first off-the-shelf detector subsystem for security CT (computed tomography) applications. The plug-and-play-type subsystem, branded as Aurora CT, includes ready-made, multislice detector boards and a data acquisition system (DAS). Read more ›

Released the X-Panel 1615 for image-guided surgery and dentistry

DT released the X-Panel 1615 to increase image-guided surgery and dental scan capabilities. This CMOS X-ray flat panel detector series has application-fitted features for X-ray systems with slender form-factors and state-of-the-art imaging performance. Read more ›

Launched the X-Panel 1412 for dental and industrial X-rays

DT launched the X-Panel 1412 to enhance advanced industrial and dental X-ray imaging applications. The X-Panel 1412 is a CMOS technology-based flat panel detector series that provides high scanning speeds yet razor-sharp images, and covers a wide energy range. Read more ›

Introduced X-Scan ME for harsh industrial environments

DT introduced the X-Scan ME to simplify multi-energy imaging in harsh industrial environments. The X-Scan ME is a product family of photon-counting line cameras and accessories for imaging needs that require material discrimination capability beyond dual-energy configurations, yet seek robustness. Read more ›

Awarded the High and New Technology Enterprise certification in China

DT announced, that its subsidiary was certified as a High and New Technology Enterprise (HNTE) in China. The HNTE status reduces the local corporate income tax rate and offers a number of other benefits related to innovation and brand value. Read more ›

Started small-series production of ME product line at its new site in France

DT launched small-series production for the ME (multi-energy) product line at its new facilities in France during Q4 2020, and shipped first X-Scan ME solutions in December.

Announced a new business structure

DT announced a new business structure, and launched the Industrial Solutions Business Unit (IBU) to scout tacit market needs, and to introduce high-tier detector solutions, beyond hardware, in which software and algorithms play a more significant role. Read more ›

Industrial Solutions Business Unit started its first operational year

DT implemented a new business structure, and the newly launched Industrial Solutions Business Unit (IBU) started its first operational year. IBU scouts tacit market needs, and introduces high-tier detector solutions beyond hardware. Read more ›

Unveiled the novel Aurora XS

DT unveiled Aurora XS to address cost and reliability drivers of the urban security market. The Aurora XS is built on a novel detector platform that makes reliable dual-energy imaging with a single-layer sensor possible. Read more ›

Expanded the X-Scan T camera family

DT expanded its X-Scan T camera family to address a wide range of industrial inspection needs. With its added value features, the camera family stands for more sustainable imaging, and promotes system efficiency and cost drivers. Read more ›

Certified as a Nasdaq ESG Transparency Partner

DT was certified as a Nasdaq ESG Transparency Partner. The recognition is presented to companies that display a high level of transparency on environmental, social, and governance issues (ESG).

DT was certified as a Nasdaq ESG Transparency Partner. The recognition is presented to companies that display a high level of transparency on environmental, social, and governance issues (ESG).

Introduced X-ACE to set a new industry standard

DT introduced X-ACE to set a new industry standard in value and mainstream medical CT imaging. The X-ACE made DT stand out from its competitors as the only on the market to enable off-the-shelf one-stop shopping for all medical CT imaging from the value to the premium segment. Read more ›

Debuted X-Panel 2222s to enhance image-guided surgery

DT debuted the X-Panel 2222s detector series to enhance image-guided surgery. For greater patient and healthcare professional experience and safety, the X-Panel 2222s equips mobile and mini C-arms with premium quality, low-dose imaging at fast scanning speeds. Read more ›

Turned 30 years old

DT turned 30 years old. All DTians were invited to a live, online global broadcast that was held the day before to celebrate the milestone together and to unite the DT community. DTians starred in this interactive show.

Launched refined values

DT launched its refined values and defined values-based behaviors and the DT Values Champion Award internally to strengthen the company culture. The renewed values clarify what DT is from a values perspective and how it reflects its values in its daily actions.

Established a talent hub in Nanjing

DT announced that it will establish a talent hub in Nanjing to boost the development of its offering beyond hardware. The Nanjing talent hub is profiled as a competence pool of software, algorithm, firmware, and electronics developers. Read more ›