This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping us to understand which sections of the website you find most interesting and useful.

Other industrial applications

X-ray has a unique ability to extract information that is unavailable through other technologies. That’s why X-rays offer highly useful benefits for a very large range of process and quality control applications in the industrial field. Improvement of safety, quality and cost efficiency with help of X-rays has a direct link to one’s brand image.

Aerospace and defence

X-ray non-destructive testing (NDT) with its ability to inspect the internal structure of objects finds many applications in the defence and aerospace industries where precision, safety, quality and reliability are paramount. X-ray may be used to inspect castings, aircraft or machine parts and munitions for internal defects. In addition, security-type applications are common, including the screening of vehicles, cargo, personnel and suspect objects using either fixed or portable systems. See the security applications section for additional information.

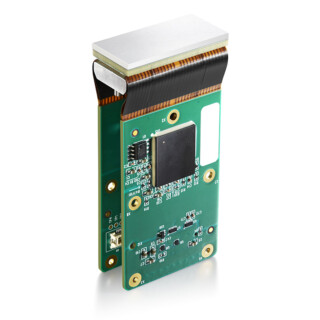

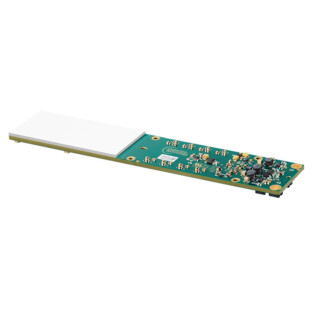

we are a leading supplier of advanced X-ray imaging solutions for 2D systems as well as for advanced 3D computed tomography (CT) applications. The range of solutions available covers low energy portable systems, up to systems utilising linear accelerators (linacs) as the radiation source with X-ray energies of up to 15MeV for penetrating very dense objects.

Agriculture

X-rays may be used in the agricultural industry for quality control and to ensure the safety of produce. Foreign objects or contaminants may be identified and produce sorted according to size or quality. Since X-ray visualizes the internal structure of objects it is possible to inspect produce, such as olives, to ensure that the pit has been removed.

Forest industry

Biofuel sorting and grading

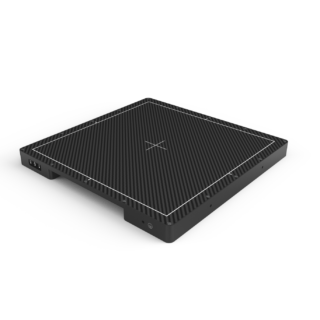

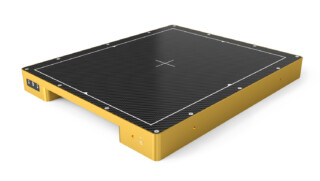

X-ray inspection may be applied to biofuels such as wood chips to identify contaminants which may cause costly damage to machinery. Inspection may be performed on bulk product on conveyor belts or on fully loaded trucks. In addition to this, dual-energy X-ray technology enables accurate, continuous in-line measurement of moisture content for the grading of biofuels.

Timber inspection for sawmills

X-ray technology, particularly computed tomography (CT), reveals the internal structure of timber prior to sawing. X-ray reveals the internal structure including heartwood, splits, knots and other flaws, and foreign objects such as nails and stones. This enable the timber to be cut to maximize yield and profitability.

Industrial process control

X-ray is a powerful tool for continuous production process control due to its ability to scan objects or material at high speed on a conveyor belts. X-ray penetrates material revealing the internal structure as well as providing information on the density or thickness of the material.

Take as an example measurement of weight-per-area or product thickness (for example of steel or wood particle board), identification foreign objects/contaminants, checking for product completeness/missing objects, measurement of product size and quality control checking.

We offer a wide range of solutions for industrial process control, including systems for use with high energies for penetrating thick steel and dual energy detectors for identifying material based on an atomic number.

Oil and gas

X-ray inspection is an established non-destructive testing (NDT) method for the inspection of pipelines, valves and pressure vessels using film-based methods. DT’s digital X-ray imaging solutions provide immediate high quality imaging without the use of chemicals thus reducing the time and cost.

In addition to 2D X-ray, DT is a leading supplier of advanced X-ray imaging solutions for precision 3D computed tomography (CT) applications. 3D computed tomography enables the internal structure of objects to be examined rapidly and non-destructively. CT may be used to inspect castings to identify defects including fractures, porosities and inclusions. Specialized CT systems may be used to inspect pipelines providing detailed cross-sectional images for verification of integrity and flow assurance.

Take as an example weld inspection, identification of cracks, measurement of pipeline wall thickness and flow assurance, diagnosis of flow abnormalities and location of blockages.

Pharmaceutical industry

X-rays are widely used in the pharmaceutical and medical device industries to ensure product safety and quality. Inspection may be performed on blister packs, vials, syringes, as well as on medical devices.

Examples of X-ray inspection use cases are detection of foreign objects/contaminants, identification of missing or broken components, checking fill levels, checking seal integrity, checking for damaged packaging, inspection of simple or complex medical devices to verify correct content and assembly.

Renewable energy

Biofuel sorting and grading

X-ray is a powerful technology for the sorting and grading of biofuels, for example wood chips and sugar cane. X-ray technology is used to identify contaminants such as rocks and soil which may cause damage to machinery, while dual-energy X-ray technology enables in-line measurement of moisture content for the grading of biofuels. Inspection may be performed on bulk product on conveyors or even on fully loaded trucks.

Inspection of wind turbine blades

X-ray technology, in particular 3D computed tomography (CT), enables rapid non-destructive, detailed inspection of the internal structure of wind turbine blades to reveal defects which could otherwise lead to costly catastrophic failures. X-ray inspection reveals material thickness and structure as well as uneven bonding, porosity, discontinuities and undulation.