This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping us to understand which sections of the website you find most interesting and useful.

We are the most trusted partner imaging the unknown by creating foresight capabilities quicker to discover and prevent threats. Our solutions contribute to the improvement of people’s health and safety daily. With us you do work that truly matters.

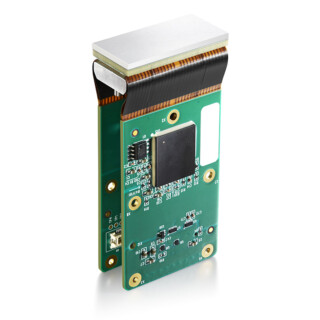

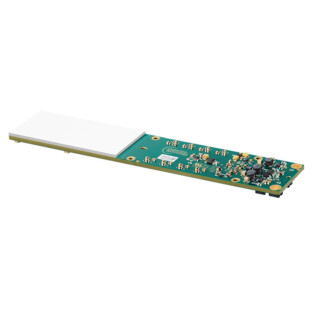

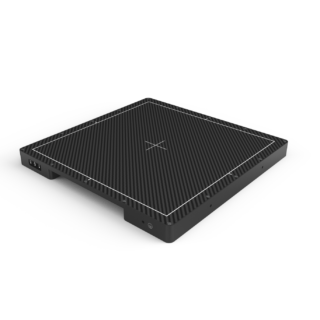

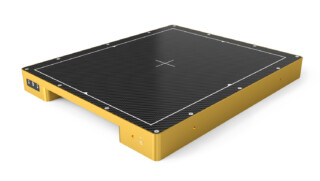

We are a global provider of off-the-shelf and customized X-ray imaging solutions for medical, security and industrial applications. Our product portfolio ranges from photodiodes to complete detector systems with ASICs, electronics, mechanics and software.

Our net sales totaled EUR 94 million in 2018. With 30% compound annual growth rate (CAGR) of net sales we have exceeded the market growth for over five years. We have 260 active customers in over 40 countries. Detection Technology employs over 500 people in Finland, China, France and the USA. The company’s shares are listed on the Nasdaq First North Finland market place.

We are looking for an experienced Equipment Engineer to join our team in Beijing. We have an immediate opening for:

Equipment Engineer

PRIMARY OBJECTIVES AND KEY CHALLENGES:

The primary objective of this position is in process development to install, setup, upgrade/modify, maintenance of manufacturing equipment to support NPI and sustaining products in manufacturing environment. Equipment engineer works cross functionally with projects, R&D, manufacturing, quality and suppliers to evaluate, selects and orders equipment that are most appropriate and cost effective to manufacture products and align to company production strategy. Equipment repair and maintenance, ensuring company overall equipment effectiveness (OEE) objectives are met.

Additional task and responsibilities as needed to fulfill department objectives.

Key challenges are to meet set targets on OEE, quality, cost and equipment knowledge “inside out”.

KNOWLEDGE / SKILLS / EXPERIENCE:

Essential

- At least 3+ years hands-on experiences in semicon equipment repair & maintenance or technical services.

- Solid knowledge in few or more manufacturing equipment; plasma cleaner, wafer dicing, die attach, wire bonder, under fill/coating and precision inspection equipment.

- Able to analyze data, attention to detail and make logical and rational conclusion.

Desirable

- Knowledge of quality control principles and methodology is an asset.

- Ability to work under pressure and independently to meet timeline.

- Familiar with Datacon, Capcom and MRSI M3 are plus.

KEY RESPONSIBILITIES AND TASKS

Manufacturing

- Coordinate projects work for process improvement activities; cycle time, cost reduction, capacity, process optimization, defect improvement, process matching, etc. and process issue trouble shooting relating to manufacturing equipment.

- Training of new resource in machine operation, troubleshooting and repair & maintenance to the level they can handle independently.

- Ensure equipment certification, properly maintained, calibrated, production ready and properly used accordingly to procedures.

- Define critical equipment spare parts and maintain inventory list.

- Oversea calibration and maintenance programs.

Quality

- Defines and writes equipment preventive maintenance procedures/schedules/routine checklist.

- Maintain good records of equipment health, manufacturers’ technical notices, upgrade, safety issues.

Productivity

- Studies performance and reliability, establish program and solution for increasing uptime and equipment problem/limitation that affect the manufacturing process and monitoring in a professional way to increase productivity.

- Participate in lean manufacturing initiatives; SMED, TPM, etc.

We offer You an opportunity to work and to develop yourself in a growing and focused High-Tech Company operating in Global Business arenas. We offer competitive salary and benefits, as well as invite You to a challenging position with full support in our international team of professionals.

Please send your application and CV for the vacancy to careers@nulldeetee.com with subject “Equipment Engineer”. For more information please contact us by phone +8610-64399970.